Formulating broiler feeds under economic pressure

In formulating broiler feeds for high-performing birds, the balance between catering to the needs of the birds accurately and getting the amino acid and nutrient quantities exactly right must be spot on. High feedstuff prices and limited availability demand creativity.

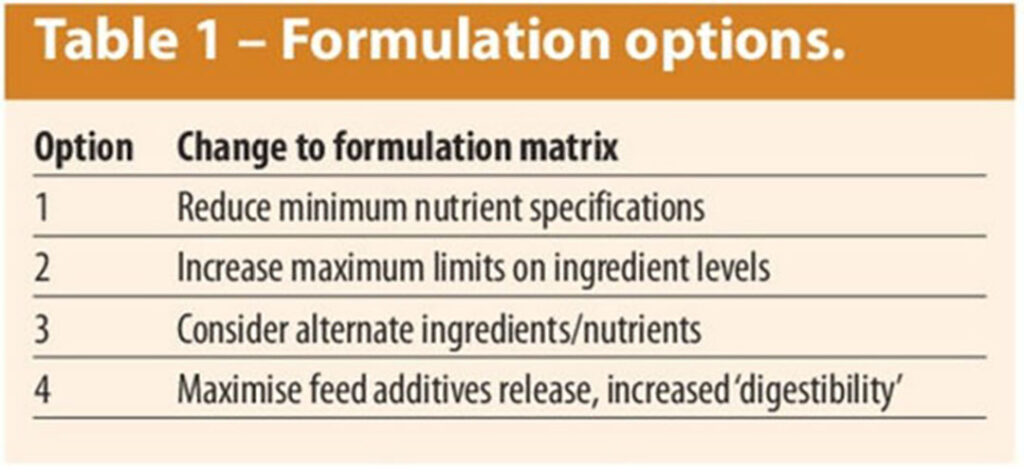

Precision feeding means that we are eliminating error and reducing the variability in nutrient levels as outlined in the formulation matrix. However, it is possible to be precise without being accurate. For example, an individual amino acid assay may show an exceptionally low variance, so it is precise but could lack accuracy by being consistently 0.2% below expectation. We never want to relax precision but we may have to reconsider what we mean by ‘accuracy’ in the current era of global uncertainty and upward economic pressure on feed costs and ingredient availability. Most of us formulate diets close to the breed recommendations, so these become our basis for ‘accuracy’ in meeting diet nutrient profiles. With current economic pressures, we may want to consider revising our goals by establishing new criteria for feed formulation. Table 1 details some options for cost-saving in a formulation that often involve re-examining our historical measures of accuracy.

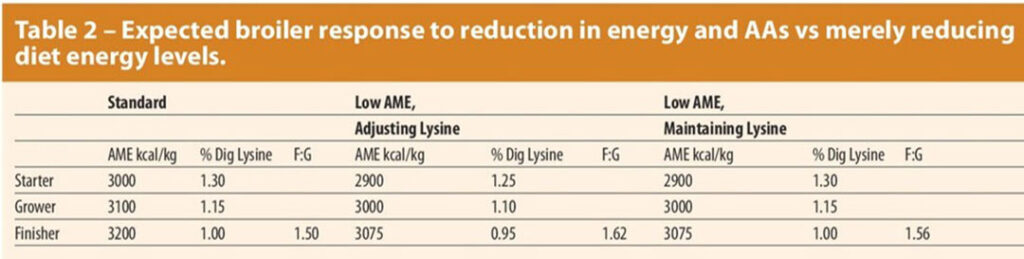

With high energy costs it is tempting to reduce feed energy levels. In the past, the converse was true, in that when feed/energy prices were high, we fed high energy diets in an attempt to ensure optimum utilisation of an expensive nutrient. Today, this concept is less valid, since the broiler is now ‘less’ responsive to energy and more responsive to amino acid intake. This change has been brought about by the reduction in fat and increase in protein in the modern broiler carcass. So, a current option is to reduce the energy level of all diets, and thus save on feed cost. Broilers still do eat to energy needs and so lower energy diets will result in an increased feed:gain ratio, but much less so than previously, since the resultant increased feed intake drives increased amino acid intake, which then offsets the expected deterioration in feed efficiency.

A second option is to relax the maximum constraints on certain ingredients. While corn and SBM levels are usually without restriction, we often impose limits on the upper levels of ‘alternative’ ingredients such as distillers grains, rice by-products and rapeseed/canola meals, etc. When the upper levels are reached in the formula this suggests cost savings from using higher levels. Current restraints are based on past knowledge of perhaps variable nutrient composition and so the decision to use more of any ingredient must be based on past knowledge of on-going quality control assays. Although we can achieve considerable detail today in such QC assays, monitoring for (consistency of) crude fibre, crude protein, fat and moisture alone, provide a sound basis for decisions on whether to use more of an individual ingredient.

The next option aimed at reducing feed costs is to consider ‘new’ alternative ingredients. In reality there are no new ingredients as such, since all monogastric nutritionists around the world have only around 19 ingredients available in sufficient quantities to sustain large-scale modern feed mills. There are certainly smaller quantities of specialised local by-products that can be used to advantage, yet these are becoming scarce. In reality, therefore, an ingredient is only novel to you, since inevitably the same ingredient has been used for many years in other regions. As such, there is a wealth of information available on the nutritive value of these ‘new’ ingredients that can be simply transposed to our formulation matrices. It’s often high feed prices in general that fuel the acceptance of novel ingredients.

There are also some options for changing the end-use of nutrients and especially energy. When we use an alternate ingredient, it merely substitutes for the supply of energy and other nutrients. In the poultry industry we rely on metabolisable energy as our basis for formulating, knowing that only a portion of this energy is used for production, the remainder being used for maintenance or lost as body heat. Another strategy within this category of ‘alternative nutrients’, is to minimise this waste energy. On farms this means keeping broilers as warm as possible, since below 24°C, the bird diverts the equivalent of 1 g feed/kg body weight/d from production to maintenance, for each 1°C decline in environmental temperature.

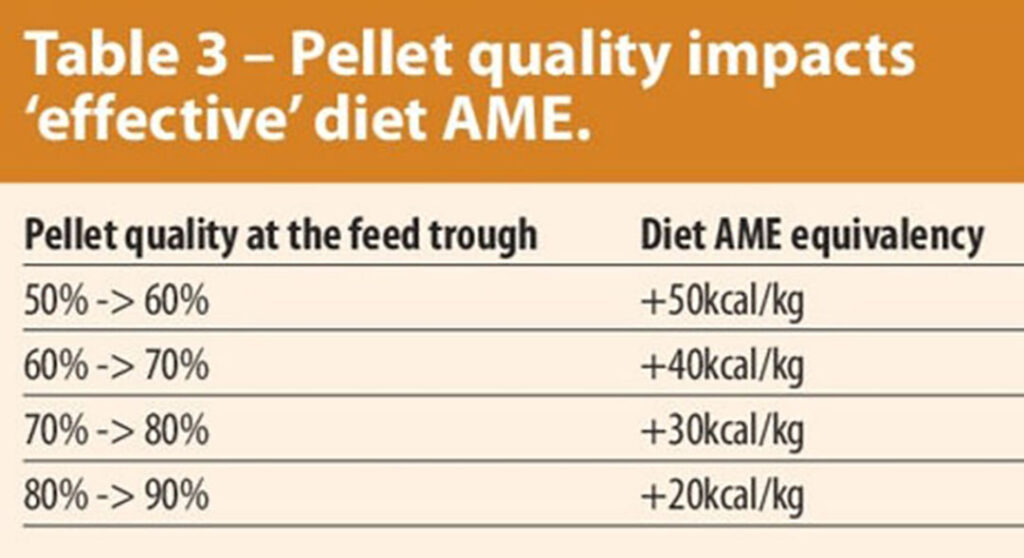

At the feed mill we also have an option for directing feed energy away from maintenance and towards growth. This option relies on optimising pellet quality independent of feed composition. As we increase pellet quality, birds need less time to eat feed, and so use less maintenance energy. Table 3 shows the energy equivalence of increasing pellet quality. If current pellet quality is 60%, increasing this to 70% is therefore equivalent to increasing diet energy by 40 kcal/kg. Alternatively, we can reduce AME by 40 kcal/kg with 70% versus 60% pellets and expect no change in performance.

With high feed prices it is especially important to review the use of feed additives that optimise nutrient release and improve ‘digestibility’. The most obvious class of such additives are the various exogenous enzymes that improve the availability of phosphorus, energy and amino acids. In most instances these different classes of enzymes are additive in terms of nutrient release since they have different target substrates or modes of action. All too often the position is taken that “well, I take energy uplift from my amylase, so I can’t expect energy release from phytase or protease”.

Such an approach is neither accurate nor precise. The energy release from phytase is invariably net energy related to removal of the phytate molecule which in effect is an ‘antigen’ and takes energy to counteract its negative effects. The energy release from an amylase, however, is obviously related simply to the improved digestibility of carbohydrate complexes. Similarly, a protease enzyme will always provide energy, since all protein/amino acids are eventually used for energy during protein turnover, hence our use of the often forgotten ‘n’ in AMEn. We also have the choice of enzyme concentration, especially for phytase, which in the current economic solution is likely to be close to 2 to 2.5 doses, assuming a single dose is around 500-600 FTUs. The economics of super-dosing or mega-dosing is greatly impacted by the cost of the enzyme. In addition to enzymes, it is also worthwhile to review the antioxidant status of feeds, along with all classes of additives intended to optimise gut health.

So perhaps it is time to review our ideas about accuracy in formulating diets. We always need precision, but our goals in terms of accuracy are sometimes a moving target due to transient economic pressures. Probably the greatest current cost savings can be made from relaxing the maximum levels on ingredients, and so the exercise becomes one of re-evaluating our levels of comfort that have become ingrained over the years. Remember that the broiler is amazingly adaptable to a vast range of nutrient densities, assuming that it can eat enough feed as the lower levels of feed energy are approached. Success in using lower levels of nutrient density is invariably negatively impacted by factors such as high stocking density and a high environmental temperature. Conversely, reducing diet energy usually has the hidden advantage of improved pellet quality.

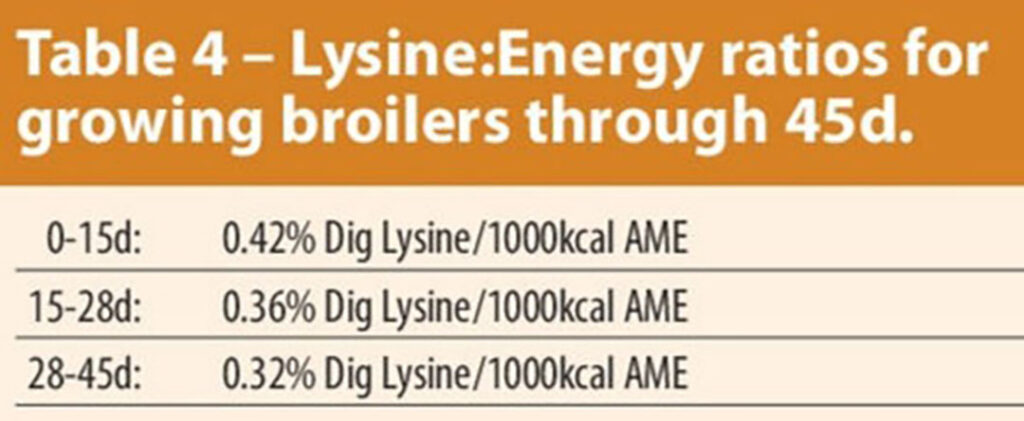

Moving the target for ‘accuracy’ in terms of diet energy will invariably impact feed efficiency, so the limit to any such change is overall economics rather than merely farm management decisions. The old concept of ‘energy:protein’ still applies, albeit now transformed into some measure of available amino acids. Table 4 provides suggested ratios of lysine to energy to be used as guidelines when considering variable nutrient density. Because of broilers’ current very positive response to amino acid intake, it is sometimes economical to change our measure of accuracy with these values, and so apply these levels of lysine and associated ‘ideal protein’ relative to, say, 950 kcal/kg. As always, a redefinition of ‘accuracy’ then becomes a local economic decision.

Read also

Wheat in Southern Brazil Impacted by Dry Weather and Frosts

Oilseed Industry. Leaders and Strategies in the Times of a Great Change

Black Sea & Danube Region: Oilseed and Vegoil Markets Within Ongoing Transfor...

Serbia. The drought will cause extremely high losses for farmers this year

2023/24 Safrinha Corn in Brazil 91% Harvested

Write to us

Our manager will contact you soon